The material of Stretch film

Source:The material of Stretch filmTime:2019-01-09Visitors:

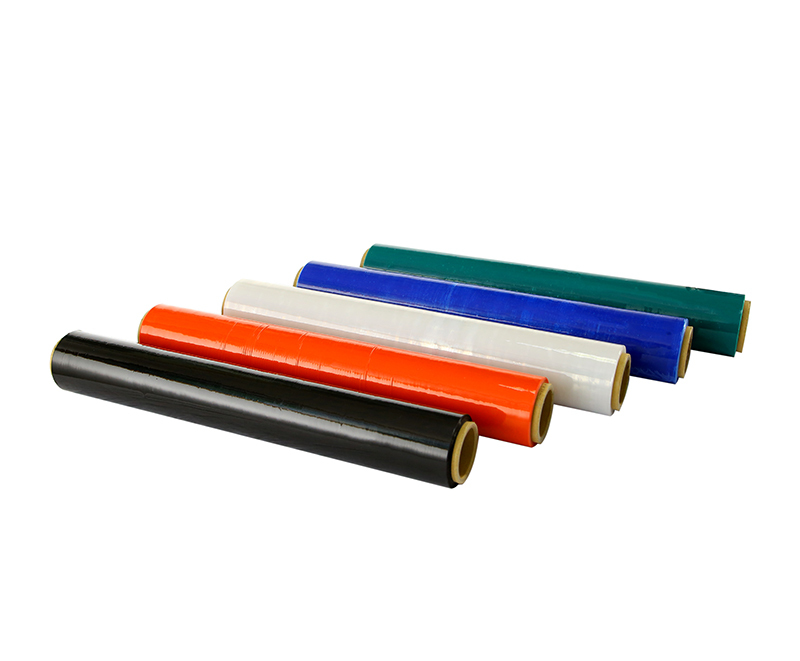

Stretch film is a relatively common packaging material, and it is also used by us. Then it is required that it must be waterproof, moisture-proof, dust-proof and damage-proof when it is used. If it has these characteristics, its manufacturing materials must be carefully selected. What materials are made of it?

1.The PE stretch film is obtained by co-extruding polypropylene particles into sheets and then stretching in both directions. Because of the orientation of the stretched molecules, the transparency of polyethylene decreases with the increase of crystallinity. At a certain degree of crystallinity, transparency increases as the molecular weight increases. The high-density polyethylene has a melting point of 132-135 ° C, and the low-density polyethylene has a low melting point (112 ° C) and a wide scale.

2. The PE stretch film is a stretch film material made of polyethylene terephthalate as a material, which is formed into a thick sheet by extrusion and then biaxially stretched. It is a colorless, transparent and shiny stretch film with excellent mechanical properties, high rigidity, hardness and resistance, puncture resistance, collision resistance, high temperature resistance and low temperature. It has good oil resistance, air tightness and aroma retention, and is one of the commonly used barrier composite stretch film substrates.

3. PE stretch film material with high-quality tackifier, heated, kneaded, cast, and then cooled by a chill roll. It has strong resistance, high elasticity, tear resistance, high viscosity, thin thickness, cold resistance, heat resistance, pressure resistance, etc. It can save materials, save labor and save time when used. It is widely used in papermaking, logistics, chemical industry, Plastic materials, building materials, food, glass, etc.

The appearance of PE stretch film brings us a lot of convenience, so with its popularity, its quality has begun to emerge in an endless stream. Therefore, in order to ensure the quality of its application, we must consider it when selecting materials.

1.The PE stretch film is obtained by co-extruding polypropylene particles into sheets and then stretching in both directions. Because of the orientation of the stretched molecules, the transparency of polyethylene decreases with the increase of crystallinity. At a certain degree of crystallinity, transparency increases as the molecular weight increases. The high-density polyethylene has a melting point of 132-135 ° C, and the low-density polyethylene has a low melting point (112 ° C) and a wide scale.

2. The PE stretch film is a stretch film material made of polyethylene terephthalate as a material, which is formed into a thick sheet by extrusion and then biaxially stretched. It is a colorless, transparent and shiny stretch film with excellent mechanical properties, high rigidity, hardness and resistance, puncture resistance, collision resistance, high temperature resistance and low temperature. It has good oil resistance, air tightness and aroma retention, and is one of the commonly used barrier composite stretch film substrates.

3. PE stretch film material with high-quality tackifier, heated, kneaded, cast, and then cooled by a chill roll. It has strong resistance, high elasticity, tear resistance, high viscosity, thin thickness, cold resistance, heat resistance, pressure resistance, etc. It can save materials, save labor and save time when used. It is widely used in papermaking, logistics, chemical industry, Plastic materials, building materials, food, glass, etc.

The appearance of PE stretch film brings us a lot of convenience, so with its popularity, its quality has begun to emerge in an endless stream. Therefore, in order to ensure the quality of its application, we must consider it when selecting materials.

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- How can we get detailed price list?

- Five common quality problems of PE protecti

- Plastic film degradation

- How to guarantee punctual shipment for our

- Gauge to Micron and Millimetre Conversion G

- What is the difference between stretch film

- Stretch film temperature requirements

- Testing the permeability of stretch film

- Electrical wire film VS electrostatic film

- The elastic characteristics of plastic film

Latest news articles

- 5 Commonly Stretch Wrapped Products & W

- How to guarantee punctual shipment for our

- Opaque Stretch Film: Security, UV Protectio

- Why stretch film is famous for wrapping goo

- How to choose high quality stretch film?

- Hong Kong International Packaging and Print

- Why does stretch film wrinkle when it is us

- Our services

- How Narrow-Width Stretch Film Streamlines S

- Stretch Film vs Shrink Film: Key Difference

- PE stretch film made of what materials?