why the stretched film is easy to break

Source:why the stretched film is easy to breakTime:2019-03-14Visitors:

Regarding the problem of stretched film breakage, why does the stretched film break off? How should it be solved? A solution to the problem that the stretched film is easily broken at high flood temperatures.

The stretched film of this polyethylene blend is hot-filled at 100 ° C.

Usually, the liquid filling film is preferably a coextruded stretch film having high temperature resistance and good strength, for example, nylon adhesive resin/PE, the inner layer is still PE, but the outer layer is nylon film. It can be heat-resistant and high-strength. It cannot be melted and blown by a fuse machine. The PP/EVA/PE co-extruded film can be blown, but the heat sealing temperature is higher at 190-200 °C. The thickness should be appropriately increased to 80-90 μm to ensure the strength of the composite film.

Another reason for stretching the film is that the pulling force is too large, and the solution is to lower the tension of the packaging machine. In fact, after sterilizing at 100 °C, the temperature is properly cooled, and the temperature of the hot filling is lowered. As long as it is carried out under the sterile room, the same packaging effect is obtained.

The temperature is influenced by the effect of the viscosity of the polymer and the moment of relaxation. When the temperature increases, the viscosity of the polymer decreases, and under the effect of stable stress, the increase of the high elastic deformation is limited, and the viscosity deformation develops rapidly, which is favorable for the polymer orientation. In the production process of stretched film, it is necessary to adhere to the stable temperature of the workshop. The quality of the production process is very important. When the temperature is controlled, the quality of the stretched film will be improved a lot, so it should be slightly hot on hot summer days and cold winters. Be careful, through other aspects of subsidies, adopt appropriate methods to modify.

The stretched film of this polyethylene blend is hot-filled at 100 ° C.

Usually, the liquid filling film is preferably a coextruded stretch film having high temperature resistance and good strength, for example, nylon adhesive resin/PE, the inner layer is still PE, but the outer layer is nylon film. It can be heat-resistant and high-strength. It cannot be melted and blown by a fuse machine. The PP/EVA/PE co-extruded film can be blown, but the heat sealing temperature is higher at 190-200 °C. The thickness should be appropriately increased to 80-90 μm to ensure the strength of the composite film.

Another reason for stretching the film is that the pulling force is too large, and the solution is to lower the tension of the packaging machine. In fact, after sterilizing at 100 °C, the temperature is properly cooled, and the temperature of the hot filling is lowered. As long as it is carried out under the sterile room, the same packaging effect is obtained.

The temperature is influenced by the effect of the viscosity of the polymer and the moment of relaxation. When the temperature increases, the viscosity of the polymer decreases, and under the effect of stable stress, the increase of the high elastic deformation is limited, and the viscosity deformation develops rapidly, which is favorable for the polymer orientation. In the production process of stretched film, it is necessary to adhere to the stable temperature of the workshop. The quality of the production process is very important. When the temperature is controlled, the quality of the stretched film will be improved a lot, so it should be slightly hot on hot summer days and cold winters. Be careful, through other aspects of subsidies, adopt appropriate methods to modify.

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- How can we get detailed price list?

- Five common quality problems of PE protecti

- Plastic film degradation

- How to guarantee punctual shipment for our

- Gauge to Micron and Millimetre Conversion G

- What is the difference between stretch film

- Stretch film temperature requirements

- Testing the permeability of stretch film

- Electrical wire film VS electrostatic film

- The elastic characteristics of plastic film

Latest news articles

- PE stretch film made of what materials?

- Why does stretch film wrinkle when it is us

- Our services

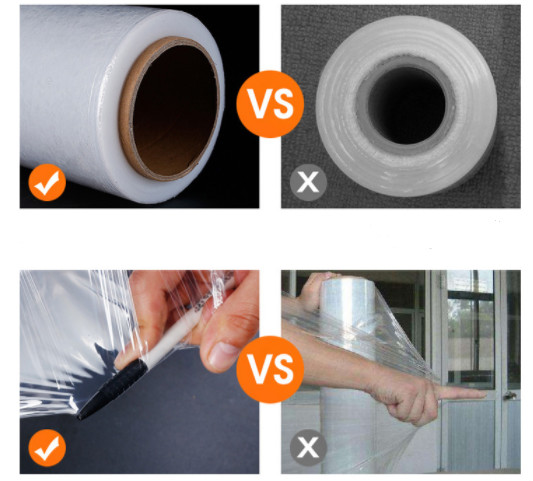

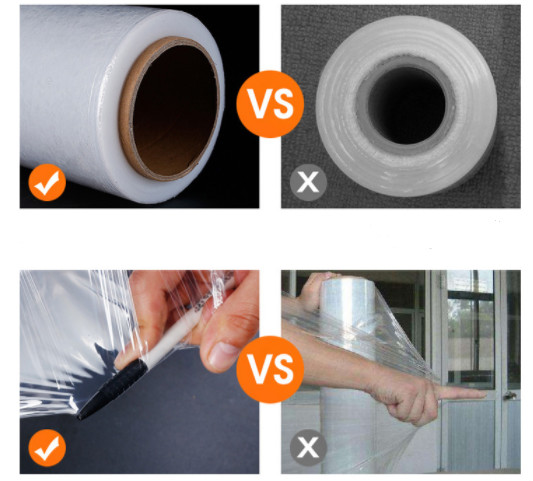

- How to choose high quality stretch film?

- Opaque Stretch Film: Security, UV Protectio

- How to guarantee punctual shipment for our

- Why stretch film is famous for wrapping goo

- How Narrow-Width Stretch Film Streamlines S

- Hong Kong International Packaging and Print

- 5 Commonly Stretch Wrapped Products & W

- Stretch Film vs Shrink Film: Key Difference