The Color of Stretch film

Source:The Color of Stretch filmTime:2019-03-18Visitors:

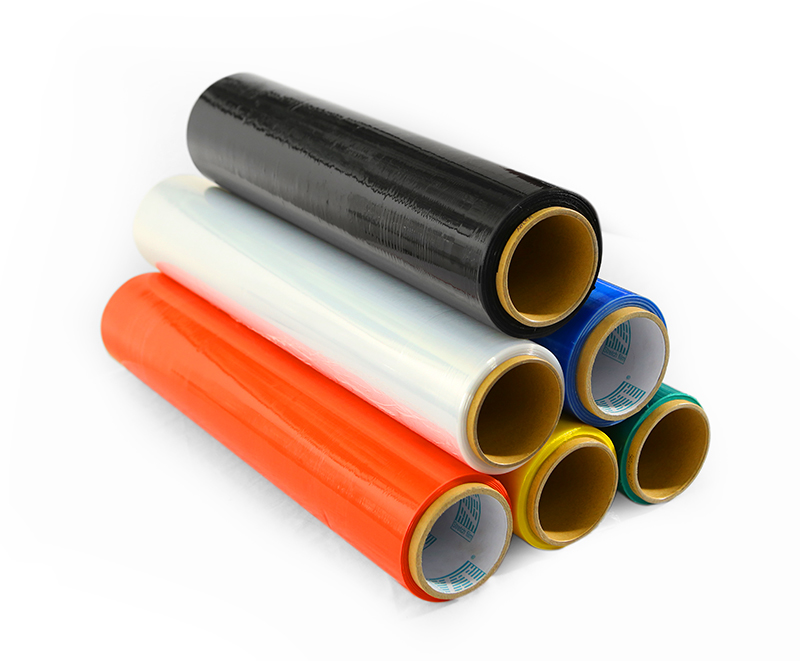

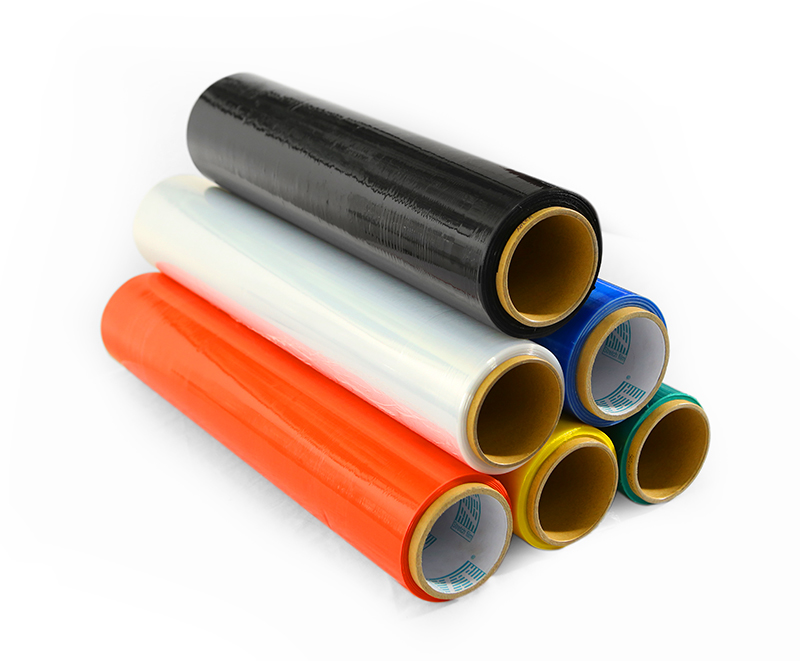

We all know that the stretch film is generally colorless and transparent, or solid color black, blue, yellow and other color films, there are few other colors, so why do some stretch wrap films appear yellowish?

The color of the stretched stretch film is light yellow, which is mainly caused by the temperature control during production. The stretched stretch film has developed into a mature production process today. Some manufacturers will try to change the formula to produce different properties of the stretched film, mainly reflected in Three aspects: color, stretch rate and self-adhesiveness. A single color change does not necessarily affect the use of the stretched film. It is known that many times the melting temperature of the film is changed due to the different melting temperatures set by the process, but not Will affect the transparency, this is a good stretch film, if the stretch rate and self-adhesive properties are reduced, it is a poor stretch film, may be mixed with other impurities.

In fact, strictly speaking, the stretched film is only colorless and color. The yellowish color is mainly caused by additives such as dov, color masterbatch or processing technology. If the color is light, the stretch rate and self-adhesiveness are not affected. If the color is not natural, the general quality will be very poor.

If the stretch film is light yellow, but the transparency, stretch rate, and self-adhesive are unchanged, and there is no odor, it can be used. If the four indicators change, do not use it again.

The color of the stretched stretch film is light yellow, which is mainly caused by the temperature control during production. The stretched stretch film has developed into a mature production process today. Some manufacturers will try to change the formula to produce different properties of the stretched film, mainly reflected in Three aspects: color, stretch rate and self-adhesiveness. A single color change does not necessarily affect the use of the stretched film. It is known that many times the melting temperature of the film is changed due to the different melting temperatures set by the process, but not Will affect the transparency, this is a good stretch film, if the stretch rate and self-adhesive properties are reduced, it is a poor stretch film, may be mixed with other impurities.

In fact, strictly speaking, the stretched film is only colorless and color. The yellowish color is mainly caused by additives such as dov, color masterbatch or processing technology. If the color is light, the stretch rate and self-adhesiveness are not affected. If the color is not natural, the general quality will be very poor.

If the stretch film is light yellow, but the transparency, stretch rate, and self-adhesive are unchanged, and there is no odor, it can be used. If the four indicators change, do not use it again.

Previous:Method of shortening stretch film

Next:Use of stretch film

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- How can we get detailed price list?

- Five common quality problems of PE protecti

- Plastic film degradation

- How to guarantee punctual shipment for our

- Gauge to Micron and Millimetre Conversion G

- What is the difference between stretch film

- Stretch film temperature requirements

- Testing the permeability of stretch film

- Electrical wire film VS electrostatic film

- The elastic characteristics of plastic film

Latest news articles

- PE stretch film made of what materials?

- Why stretch film is famous for wrapping goo

- 5 Commonly Stretch Wrapped Products & W

- Stretch Film vs Shrink Film: Key Difference

- How to choose high quality stretch film?

- How Narrow-Width Stretch Film Streamlines S

- Why does stretch film wrinkle when it is us

- Hong Kong International Packaging and Print

- Opaque Stretch Film: Security, UV Protectio

- How to guarantee punctual shipment for our

- Our services