The Ultimate Guide to Pre-Stretch Film: Why it's the Secret

Source:The Ultimate Guide to Pre-Stretch Film: Why it's the SecretTime:2024-04-01Visitors:

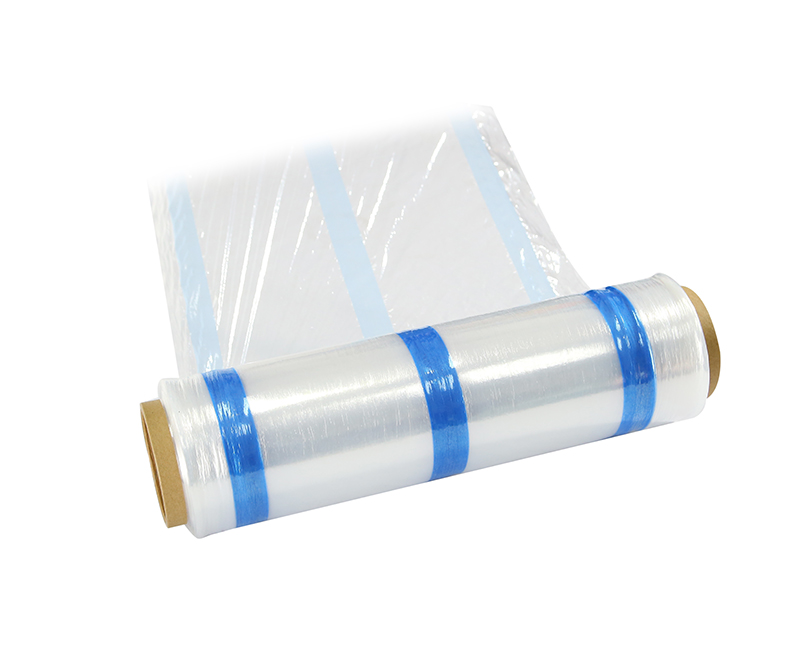

In today's fast-paced business world, secure and efficient packaging is vital to protect your products during transportation and storage. And when it comes to packaging solutions, pre-stretch film is the ultimate secret weapon.

In this comprehensive guide, we'll delve into the world of pre-stretch film, exploring its benefits, applications, and why it should be an integral part of your packaging strategy. With its unique properties, pre-stretch film provides superior load stability and tamper resistance, ensuring that your products arrive at their destination in pristine condition. Its ability to stretch further than traditional stretch film means you'll need less material, saving both cost and the environment. Whether you're packaging pallets, furniture, or industrial equipment, pre-stretch film offers unbeatable strength and protection.

In this guide, we'll walk you through the different types of pre-stretch film and their features. We'll also provide practical tips on choosing the right pre-stretch film for your specific packaging needs. So, if you're ready to take your packaging game to the next level, let's dive into the world of pre-stretch film and discover why it's the secret weapon for secure packaging.

One of the primary reasons to choose pre-stretch film is its exceptional memory and ability to tighten around the load. As the film is applied, it naturally tightens, ensuring secure and stable packaging. This feature greatly reduces the risk of load shifting during transit.

Pre-stretch film offers significant cost-saving benefits. Due to its thinner gauge, it requires less material compared to traditional film, resulting in reduced packaging costs. Moreover, the unique stretching process allows for increased film recovery, enhancing the wrap's strength and reducing the need for excessive wrapping.

Pre-stretch film operates by employing a specialized stretching mechanism during the packaging process. Unlike traditional stretch film, which relies solely on manual tension, pre-stretch film undergoes mechanical stretching before application. This pre-stretching process elongates the film, aligns its molecules, and enhances its strength and elasticity, resulting in superior load retention and protection.

Machine pre-stretch film is designed for use with automatic stretch wrapping machines. It undergoes pre-stretching within the machine before being applied to the load, ensuring consistent stretching and optimal load stability.

Hand pre-stretch film is suitable for manual wrapping applications. While it may not undergo the same level of pre-stretching as machine film, hand pre-stretch film still offers excellent load retention and tamper resistance when applied correctly.

When selecting pre-stretch film for your packaging needs, consider factors such as load characteristics, application method, and environmental conditions. Choose the appropriate film type and specifications to ensure optimal performance and protection.

Regular maintenance and calibration of stretch wrapping equipment are essential to ensure optimal performance and reliable load stability. Neglecting equipment maintenance can lead to subpar film application and compromised packaging integrity.

Ignoring factors such as load weight distribution, sharp edges, and protrusions can result in uneven film application and inadequate load containment. Proper assessment and preparation of the load are crucial to ensure effective packaging.

The superior stretching capabilities of pre-stretch film translate to less material usage compared to traditional stretch film. This not only reduces packaging costs but also minimizes environmental impact by decreasing waste generation.

In this comprehensive guide, we'll delve into the world of pre-stretch film, exploring its benefits, applications, and why it should be an integral part of your packaging strategy. With its unique properties, pre-stretch film provides superior load stability and tamper resistance, ensuring that your products arrive at their destination in pristine condition. Its ability to stretch further than traditional stretch film means you'll need less material, saving both cost and the environment. Whether you're packaging pallets, furniture, or industrial equipment, pre-stretch film offers unbeatable strength and protection.

In this guide, we'll walk you through the different types of pre-stretch film and their features. We'll also provide practical tips on choosing the right pre-stretch film for your specific packaging needs. So, if you're ready to take your packaging game to the next level, let's dive into the world of pre-stretch film and discover why it's the secret weapon for secure packaging.

Benefits of Using Pre-Stretch Film for Secure Packaging

Enhanced Load Security and Stability

One of the primary reasons to choose pre-stretch film is its exceptional memory and ability to tighten around the load. As the film is applied, it naturally tightens, ensuring secure and stable packaging. This feature greatly reduces the risk of load shifting during transit.

Cost Savings

Pre-stretch film offers significant cost-saving benefits. Due to its thinner gauge, it requires less material compared to traditional film, resulting in reduced packaging costs. Moreover, the unique stretching process allows for increased film recovery, enhancing the wrap's strength and reducing the need for excessive wrapping.

How Pre-Stretch Film Works

Pre-stretch film operates by employing a specialized stretching mechanism during the packaging process. Unlike traditional stretch film, which relies solely on manual tension, pre-stretch film undergoes mechanical stretching before application. This pre-stretching process elongates the film, aligns its molecules, and enhances its strength and elasticity, resulting in superior load retention and protection.

Types of Pre-Stretch Film Available

Machine Pre-stretch Film

Machine pre-stretch film is designed for use with automatic stretch wrapping machines. It undergoes pre-stretching within the machine before being applied to the load, ensuring consistent stretching and optimal load stability.

Hand Pre-stretch Film

Hand pre-stretch film is suitable for manual wrapping applications. While it may not undergo the same level of pre-stretching as machine film, hand pre-stretch film still offers excellent load retention and tamper resistance when applied correctly.

Choosing the Right Pre-Stretch Film for Your Packaging Needs

When selecting pre-stretch film for your packaging needs, consider factors such as load characteristics, application method, and environmental conditions. Choose the appropriate film type and specifications to ensure optimal performance and protection.

Tips for Proper Application of Pre-Stretch Film

Ensure Proper Film Tension

Maintain consistent tension during the wrapping process to achieve optimal load stability and containment. Overstretching or understretching the film can compromise its effectiveness and result in load failure.Use Adequate Overlap

Ensure sufficient overlap between film layers to create a secure seal and prevent moisture and dust ingress. Proper overlap enhances load stability and provides additional protection against punctures and tears.Common Mistakes to Avoid When Using Pre-Stretch Film

Neglecting Equipment Maintenance

Regular maintenance and calibration of stretch wrapping equipment are essential to ensure optimal performance and reliable load stability. Neglecting equipment maintenance can lead to subpar film application and compromised packaging integrity.

Overlooking Load Configuration

Ignoring factors such as load weight distribution, sharp edges, and protrusions can result in uneven film application and inadequate load containment. Proper assessment and preparation of the load are crucial to ensure effective packaging.

Cost Savings and Environmental Benefits of Using Pre-Stretch Film

Reduced Material Usage

The superior stretching capabilities of pre-stretch film translate to less material usage compared to traditional stretch film. This not only reduces packaging costs but also minimizes environmental impact by decreasing waste generation.

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- How can we get detailed price list?

- Five common quality problems of PE protecti

- Plastic film degradation

- How to guarantee punctual shipment for our

- Gauge to Micron and Millimetre Conversion G

- What is the difference between stretch film

- Stretch film temperature requirements

- Testing the permeability of stretch film

- Electrical wire film VS electrostatic film

- The elastic characteristics of plastic film

Latest news articles

- Hong Kong International Packaging and Print

- How to guarantee punctual shipment for our

- How to choose high quality stretch film?

- 5 Commonly Stretch Wrapped Products & W

- PE stretch film made of what materials?

- Our services

- Stretch Film vs Shrink Film: Key Difference

- Opaque Stretch Film: Security, UV Protectio

- Why does stretch film wrinkle when it is us

- How Narrow-Width Stretch Film Streamlines S

- Why stretch film is famous for wrapping goo