A Complete Guide to Shrink Wrap: Types, Uses, and Tips for S

Source:A Complete Guide to Shrink Wrap: Types, Uses, and Tips for STime:2025-04-11Visitors:

Shrink wrap is a packaging powerhouse, trusted across industries to protect, secure, and showcase products. From safeguarding pallets in warehouses to sealing food for freshness, this versatile plastic film shrinks tightly around objects when heated, creating a durable, tamper-evident barrier. Whether you’re a logistics manager, a small business owner, or a DIY enthusiast, understanding shrink wrap can transform how you protect your goods.

In this complete guide, we’ll explore everything you need to know about shrink wrap—its types, applications, equipment, benefits, and more. We’ll also compare it to alternatives like stretch wrap, dive into eco-friendly options, and share practical tips to ensure flawless results. Ready to master shrink wrap? Let’s dive in.

1. Wrap the item in shrink film (rolls, bags, or tubing).

2. Seal any open edges, if needed.

3. Apply heat using a heat gun or shrink tunnel, causing the film to shrink and mold to the item’s contours.

This creates a secure, professional-looking package that protects against dust, moisture, and tampering.

● Common Uses: Retail packaging (e.g., toys, cosmetics), food wrapping (e.g., produce, baked goods), and multipacks.

● Advantages: Safe for direct food contact, recyclable, and widely compatible with shrink equipment.

● Common Uses: Small products like CDs, DVDs, candles, or gift baskets.

● Advantages: Affordable and glossy, ideal for showcasing items. However, it’s less suitable for food or high-heat environments.

● Common Uses: Pallet wrapping, bundling heavy items (e.g., bottled water, lumber), and large-scale packaging.

● Advantages: Exceptional durability for oversized or irregular loads, often used in logistics.

● Printed Shrink Wrap: Custom designs for branding, offered by companies like Dongguan Zhiteng Plastic Product Co., Ltd. under their product range.

● Steps:

1. Wrap the item loosely in shrink film, ensuring full coverage.

2. Seal open edges with tape or a sealer to create a closed package.

3. Apply heat evenly with a heat gun, moving in a steady motion to shrink the film tightly.

● Best For: Small businesses, retail packaging, or DIY projects like gift wrapping.

○ L-Bar Sealers: Cut and seal film in one step for small to medium volumes.

○ Shrink Tunnels: Convey items through a heated chamber for high-speed, uniform shrinking.

○ Combo Systems: Integrate sealing and shrinking for efficiency.

● Benefits: Speed and consistency, ideal for high-volume operations like food processing or logistics.

● Example: A beverage company bundling 24-packs of water bottles for distribution.

● Heat Settings: Too much heat can burn film; too little leaves loose spots.

● Ventilation: Ensure proper airflow to avoid fumes, especially with PVC.

● Bundling: Groups items like pipes, tiles, or canned goods for stability.

● Multipacks: Combines products for promotions (e.g., shampoo and conditioner bundles).

● Compliance: Meets FDA standards for direct food contact.

● Moving and Storage: Secures furniture or household items. Example: Shrink-wrapping a couch to keep it clean during a move.

● DIY Projects: Gift baskets, crafts, or hobbyist packaging.

When to Choose:

● Shrink Wrap: For sealing individual items or weatherproofing (e.g., a boat).

● Stretch Wrap: For securing pallets or unstable loads (e.g., Dongguan Zhiteng’s stretch films for logistics).

● Protection: Shields against dust, moisture, UV rays, and scratches, ideal for long-term storage or shipping.

● Tamper Evidence: A tight seal shows if a package has been opened, boosting consumer trust.

● Aesthetics: Glossy, professional appearance enhances retail appeal.

● Versatility: Wraps irregular shapes—think furniture, multipacks, or machinery.

● Cost-Effectiveness: Affordable, with low material costs even for small-scale use.

For example, a small business shrink-wrapping handmade soaps saves on packaging while ensuring a polished look.

● Equipment Costs: Heat guns are affordable ($30–$100), but shrink tunnels cost thousands, a barrier for startups.

● Environmental Concerns: Plastic waste raises sustainability questions, though recyclable options exist.

● Heat Sensitivity: Delicate items like electronics may warp under heat.

● Learning Curve: Overheating or uneven application can lead to wrinkles or burns.

● Heat Guns: Portable and affordable, perfect for small-scale wrapping. Example: Wrapping gift baskets.

● Shrink Wrap Machines:

○ L-Bar Sealers: Seal and cut in one motion for medium volumes.

○ Shrink Tunnels: High-speed shrinking for large operations.

○ Combo Systems: All-in-one solutions for efficiency.

● Accessories: Dispensers for rolls, cutters for precision, and sealing tape for manual setups.

● High Volume: Invest in a shrink tunnel for speed (e.g., a food manufacturer wrapping 1,000 trays daily).

● Budget: Start with manual tools and scale up as needed.

● Recyclable Films: Polyolefin and polyethylene are widely recyclable. Check local facilities.

● Biodegradable Options: Emerging bio-based films break down naturally.

● Down-Gauging: Thinner films (e.g., 60 gauge) reduce plastic use without sacrificing strength.

● Certifications: Look for ROHS-compliant films, like Dongguan Zhiteng’s green packaging solutions.

Tip: Partner with suppliers offering eco-friendly films to align with consumer values.

● Product Type: Fragile items need polyolefin; heavy loads require polyethylene.

● Environment: Outdoor storage demands UV-resistant films; retail needs clarity.

● Budget: PVC is cheapest, but polyolefin offers long-term value.

● Aesthetics: Printed shrink wrap (e.g., Dongguan Zhiteng’s custom options) boosts branding.

● 100–150 Gauge: Medium loads like multipacks or electronics.

● 200+ Gauge: Heavy pallets or industrial goods.

● Can you provide samples or custom gauges?

● What’s the lead time for printed shrink wrap?

● Avoid Overheating: Use low heat initially to prevent burns or wrinkles.

● Ensure Even Application: Move the heat gun steadily for uniform shrinking.

● Seal Securely: Loose seals lead to weak spots—double-check edges.

● Test Thickness: Too thin risks tearing; too thick wastes material.

● Safety First: Wear gloves, work in a ventilated area, and keep heat away from flammables.

Example: A retailer shrink-wrapping candles should use polyolefin (60 gauge), apply heat evenly, and test a sample to avoid melting wax.

Ready to get started? Evaluate your requirements, test different films, and partner with a trusted supplier. At Dongguan Zhiteng Plastic Product Co., Ltd., we’ve spent over 23 years perfecting packaging solutions, from shrink wrap to stretch film. Contact us at zt@dgztpacking.com or +86-13427862379 to find the perfect shrink wrap for your business. Let’s wrap up a brighter future together.

A: Yes, polyolefin and polyethylene shrink wrap are recyclable. Check with local recycling centers for guidelines.

Q: Can I shrink wrap food?

A: Absolutely, but use food-safe polyolefin shrink wrap to meet FDA standards.

Q: What’s the difference between shrink wrap and stretch wrap?

A: Shrink wrap shrinks with heat for sealing; stretch wrap stretches to secure loads like pallets.

Q: How thick should my shrink wrap be?

A: Choose 60–80 gauge for light items, 100–150 for medium, and 200+ for heavy loads.

In this complete guide, we’ll explore everything you need to know about shrink wrap—its types, applications, equipment, benefits, and more. We’ll also compare it to alternatives like stretch wrap, dive into eco-friendly options, and share practical tips to ensure flawless results. Ready to master shrink wrap? Let’s dive in.

What is Shrink Wrap?

Shrink wrap, also known as shrink film, is a plastic material—typically made from polymers like polyolefin, PVC, or polyethylene—that shrinks when heated to conform tightly to the shape of an object. The heat activates the film’s “memory,” causing it to contract and create a snug, protective seal without adhesives.

How It Works

The shrink wrapping process is simple yet effective:1. Wrap the item in shrink film (rolls, bags, or tubing).

2. Seal any open edges, if needed.

3. Apply heat using a heat gun or shrink tunnel, causing the film to shrink and mold to the item’s contours.

This creates a secure, professional-looking package that protects against dust, moisture, and tampering.

A Brief History

Shrink wrap emerged in the mid-20th century as a packaging innovation, evolving from basic polyethylene films to advanced, multi-layered materials. Today, companies like Dongguan Zhiteng Plastic Product Co., Ltd., with over 23 years of expertise, produce high-quality shrink films tailored to diverse needs.Types of Shrink Wrap

Not all shrink wrap is the same. Different materials offer unique properties, making them suited for specific applications. Here’s a breakdown of the main types:Polyolefin Shrink Wrap

● Properties: Durable, versatile, and food-safe, with excellent clarity and strength. It’s resistant to temperature fluctuations.● Common Uses: Retail packaging (e.g., toys, cosmetics), food wrapping (e.g., produce, baked goods), and multipacks.

● Advantages: Safe for direct food contact, recyclable, and widely compatible with shrink equipment.

PVC Shrink Wrap

● Properties: High clarity and cost-effective but less environmentally friendly due to chlorine content.● Common Uses: Small products like CDs, DVDs, candles, or gift baskets.

● Advantages: Affordable and glossy, ideal for showcasing items. However, it’s less suitable for food or high-heat environments.

Polyethylene Shrink Wrap

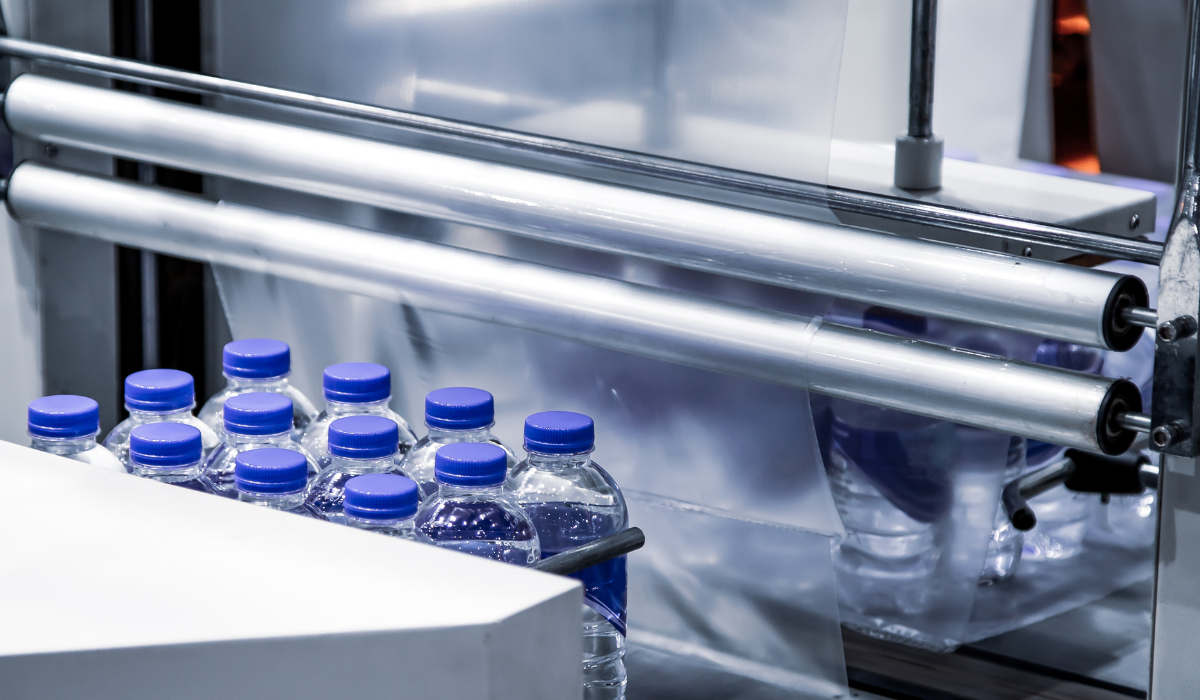

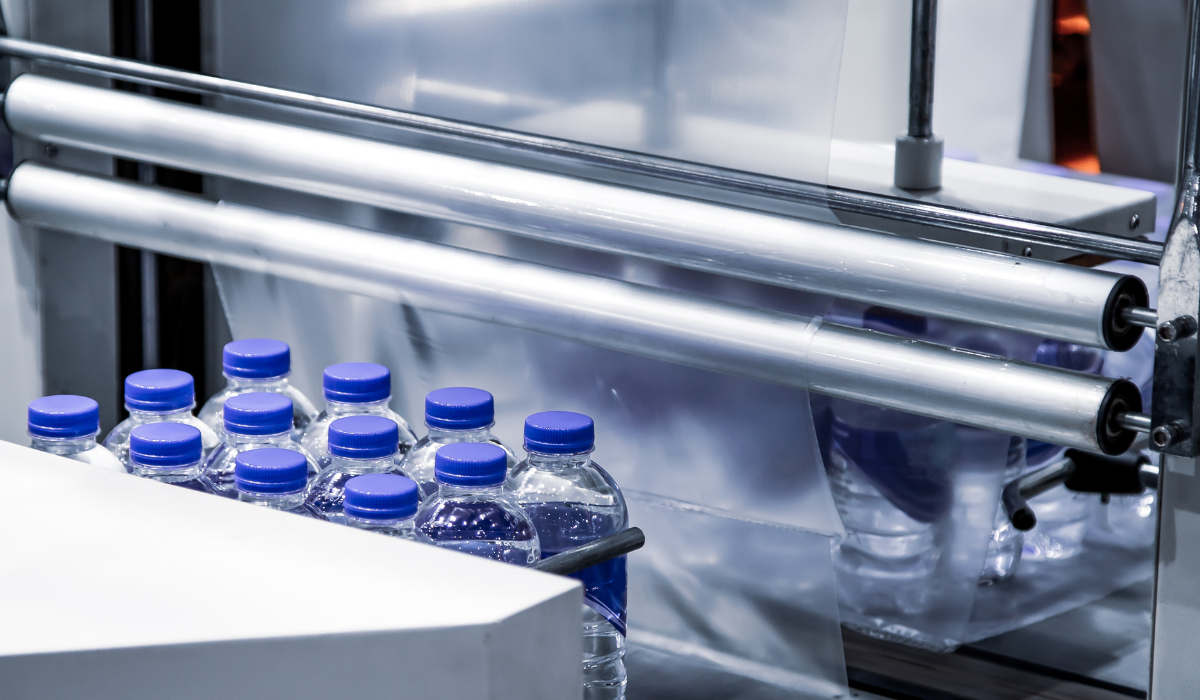

● Properties: Thick, strong, and available in heavier gauges for industrial use.● Common Uses: Pallet wrapping, bundling heavy items (e.g., bottled water, lumber), and large-scale packaging.

● Advantages: Exceptional durability for oversized or irregular loads, often used in logistics.

Other Types

● Cross-Linked Shrink Wrap: Enhanced strength and shrink performance for demanding applications.● Printed Shrink Wrap: Custom designs for branding, offered by companies like Dongguan Zhiteng Plastic Product Co., Ltd. under their product range.

Comparison Table: Types of Shrink Wrap

| Type | Properties | Common Uses | Cost |

| Polyolefin | Durable, food-safe, clear | Food, retail, multipacks | Moderate |

| PVC | High clarity, affordable | CDs, DVDs, small products | Low |

| Polyethylene | Thick, strong, heavy-duty | Pallets, industrial goods | High |

The Shrink Wrapping Process

Shrink wrapping can be done manually or with automated systems, depending on your scale and needs. Here’s how it works:

Manual Shrink Wrapping

● Tools: Heat gun, shrink wrap rolls or bags, sealing tape, or a handheld sealer.● Steps:

1. Wrap the item loosely in shrink film, ensuring full coverage.

2. Seal open edges with tape or a sealer to create a closed package.

3. Apply heat evenly with a heat gun, moving in a steady motion to shrink the film tightly.

● Best For: Small businesses, retail packaging, or DIY projects like gift wrapping.

Automated Shrink Wrapping

● Equipment:○ L-Bar Sealers: Cut and seal film in one step for small to medium volumes.

○ Shrink Tunnels: Convey items through a heated chamber for high-speed, uniform shrinking.

○ Combo Systems: Integrate sealing and shrinking for efficiency.

● Benefits: Speed and consistency, ideal for high-volume operations like food processing or logistics.

● Example: A beverage company bundling 24-packs of water bottles for distribution.

Key Considerations

● Film Thickness: Measured in gauge (e.g., 60–200 gauge), thicker films suit heavier items.● Heat Settings: Too much heat can burn film; too little leaves loose spots.

● Ventilation: Ensure proper airflow to avoid fumes, especially with PVC.

Applications of Shrink Wrap

Shrink wrap’s versatility makes it a go-to solution across industries and personal scenarios. Here are its top uses:Industrial and Logistics

● Pallet Wrapping: Secures pallets for transport, protecting against weather and shifting. Example: A logistics firm shrink-wrapping machinery for overseas shipping.● Bundling: Groups items like pipes, tiles, or canned goods for stability.

Retail and Consumer Goods

● Product Packaging: Enhances aesthetics and tamper evidence for items like books, electronics, or cosmetics.● Multipacks: Combines products for promotions (e.g., shampoo and conditioner bundles).

Food Industry

● Freshness and Hygiene: Food-safe polyolefin shrink wrap seals cheese, meat, or produce. Example: A bakery shrink-wrapping pastries to extend shelf life.● Compliance: Meets FDA standards for direct food contact.

Personal and Specialty Uses

● Boat Wrapping: Protects boats during winter storage from moisture and UV damage.● Moving and Storage: Secures furniture or household items. Example: Shrink-wrapping a couch to keep it clean during a move.

● DIY Projects: Gift baskets, crafts, or hobbyist packaging.

Shrink Wrap vs. Stretch Wrap

Confused about shrink wrap vs. stretch wrap? They’re often mistaken for each other but serve different purposes:| Feature | Shrink Wrap | Stretch Wrap |

| Definition | Shrinks with heat to seal tightly | Stretches elastically to secure loads |

| Primary Use | Protection, tamper evidence, aesthetics | Load containment, pallet stability |

| Application | Retail, food, bundling | Warehousing, shipping |

| Example | Shrink-wrapped DVDs | Stretch-wrapped pallets |

● Shrink Wrap: For sealing individual items or weatherproofing (e.g., a boat).

● Stretch Wrap: For securing pallets or unstable loads (e.g., Dongguan Zhiteng’s stretch films for logistics).

Benefits of Shrink Wrap

Why choose shrink wrap? Here are its top advantages:● Protection: Shields against dust, moisture, UV rays, and scratches, ideal for long-term storage or shipping.

● Tamper Evidence: A tight seal shows if a package has been opened, boosting consumer trust.

● Aesthetics: Glossy, professional appearance enhances retail appeal.

● Versatility: Wraps irregular shapes—think furniture, multipacks, or machinery.

● Cost-Effectiveness: Affordable, with low material costs even for small-scale use.

For example, a small business shrink-wrapping handmade soaps saves on packaging while ensuring a polished look.

Limitations of Shrink Wrap

No solution is perfect. Here are shrink wrap’s challenges:● Equipment Costs: Heat guns are affordable ($30–$100), but shrink tunnels cost thousands, a barrier for startups.

● Environmental Concerns: Plastic waste raises sustainability questions, though recyclable options exist.

● Heat Sensitivity: Delicate items like electronics may warp under heat.

● Learning Curve: Overheating or uneven application can lead to wrinkles or burns.

Equipment and Tools for Shrink Wrapping

The right tools make shrink wrapping efficient and effective. Here’s what’s available:● Heat Guns: Portable and affordable, perfect for small-scale wrapping. Example: Wrapping gift baskets.

● Shrink Wrap Machines:

○ L-Bar Sealers: Seal and cut in one motion for medium volumes.

○ Shrink Tunnels: High-speed shrinking for large operations.

○ Combo Systems: All-in-one solutions for efficiency.

● Accessories: Dispensers for rolls, cutters for precision, and sealing tape for manual setups.

Choosing Equipment

● Low Volume: A heat gun and manual dispenser suffice for small businesses.● High Volume: Invest in a shrink tunnel for speed (e.g., a food manufacturer wrapping 1,000 trays daily).

● Budget: Start with manual tools and scale up as needed.

Eco-Friendly Shrink Wrap Options

Sustainability is a priority for modern businesses. Shrink wrap is adapting:● Recyclable Films: Polyolefin and polyethylene are widely recyclable. Check local facilities.

● Biodegradable Options: Emerging bio-based films break down naturally.

● Down-Gauging: Thinner films (e.g., 60 gauge) reduce plastic use without sacrificing strength.

● Certifications: Look for ROHS-compliant films, like Dongguan Zhiteng’s green packaging solutions.

Tip: Partner with suppliers offering eco-friendly films to align with consumer values.

How to Choose the Right Shrink Wrap

Selecting shrink wrap depends on your needs. Consider these factors:● Product Type: Fragile items need polyolefin; heavy loads require polyethylene.

● Environment: Outdoor storage demands UV-resistant films; retail needs clarity.

● Budget: PVC is cheapest, but polyolefin offers long-term value.

● Aesthetics: Printed shrink wrap (e.g., Dongguan Zhiteng’s custom options) boosts branding.

Thickness Guide

● 60–80 Gauge: Light items like books or CDs.● 100–150 Gauge: Medium loads like multipacks or electronics.

● 200+ Gauge: Heavy pallets or industrial goods.

Questions for Suppliers

● Are films food-safe or recyclable?● Can you provide samples or custom gauges?

● What’s the lead time for printed shrink wrap?

Tips for Effective Shrink Wrapping

Avoid pitfalls and get professional results with these tips:● Avoid Overheating: Use low heat initially to prevent burns or wrinkles.

● Ensure Even Application: Move the heat gun steadily for uniform shrinking.

● Seal Securely: Loose seals lead to weak spots—double-check edges.

● Test Thickness: Too thin risks tearing; too thick wastes material.

● Safety First: Wear gloves, work in a ventilated area, and keep heat away from flammables.

Example: A retailer shrink-wrapping candles should use polyolefin (60 gauge), apply heat evenly, and test a sample to avoid melting wax.

Conclusion

Shrink wrap is a game-changer for packaging, offering protection, aesthetics, and versatility across industries and personal projects. Whether you’re sealing pallets, enhancing retail displays, or winterizing a boat, the right shrink wrap—be it polyolefin, PVC, or polyethylene—can meet your needs. By understanding types, equipment, and best practices, you’ll unlock its full potential.Ready to get started? Evaluate your requirements, test different films, and partner with a trusted supplier. At Dongguan Zhiteng Plastic Product Co., Ltd., we’ve spent over 23 years perfecting packaging solutions, from shrink wrap to stretch film. Contact us at zt@dgztpacking.com or +86-13427862379 to find the perfect shrink wrap for your business. Let’s wrap up a brighter future together.

FAQ

Q: Is shrink wrap recyclable?A: Yes, polyolefin and polyethylene shrink wrap are recyclable. Check with local recycling centers for guidelines.

Q: Can I shrink wrap food?

A: Absolutely, but use food-safe polyolefin shrink wrap to meet FDA standards.

Q: What’s the difference between shrink wrap and stretch wrap?

A: Shrink wrap shrinks with heat for sealing; stretch wrap stretches to secure loads like pallets.

Q: How thick should my shrink wrap be?

A: Choose 60–80 gauge for light items, 100–150 for medium, and 200+ for heavy loads.

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- How can we get detailed price list?

- Five common quality problems of PE protecti

- Plastic film degradation

- How to guarantee punctual shipment for our

- Gauge to Micron and Millimetre Conversion G

- What is the difference between stretch film

- Stretch film temperature requirements

- Testing the permeability of stretch film

- Electrical wire film VS electrostatic film

- The elastic characteristics of plastic film

Latest news articles

- Stretch Film vs Shrink Film: Key Difference

- Hong Kong International Packaging and Print

- Our services

- How to guarantee punctual shipment for our

- How to choose high quality stretch film?

- PE stretch film made of what materials?

- Opaque Stretch Film: Security, UV Protectio

- Why stretch film is famous for wrapping goo

- 5 Commonly Stretch Wrapped Products & W

- How Narrow-Width Stretch Film Streamlines S

- Why does stretch film wrinkle when it is us