Stretch film temperature requirements

Source:Stretch film temperature requirementsTime:2019-03-07Visitors:

Stretch film in the process of manufacturing, not only has strict standards on materials, but also has strict requirements on external factors, especially temperature, temperature can be said to have a great impact on its manufacture, in the manufacturing process The autoclave and gas-filling block control stage occupies an appropriate position. The high-temperature and high-pressure steam maintenance can remove the free water in the film blank, and the green body particles are tightened and close together, which can reduce the thermal expansion and damage caused by the rapid transpiration of water.

Warming phase

Under the premise of ensuring that the stretched film blank is not affected by the vapor, the temperature rise time should be as short as possible, and it is only necessary to continuously and uniformly deliver steam to the maintenance room for 1.0 to 1.5 hours.

Constant temperature stage

The constant temperature phase is an important stage in which the body is hydrated and hydrothermally composed to increase the strength. As the constant temperature time extends, the more the hydrates accumulate, the faster the strength increases. However, after the constant temperature reaches a certain time, the strength increases and the start becomes slower. Different material ratios, different production processes, and the output of the aerated block blanks have a corresponding constant temperature moment. For example, under the hot and humid conditions of 96 to 100 ° C, the constant temperature is 8 hours in spring and autumn, 7 hours in summer and 10 hours in winter. In the cooling stage, when the output is large and the maintenance room is not enough space, the maintenance room door should be opened and the rapid cooling will be adopted, which will cause the temperature difference stress between the surface of the stretched film body to cause the surface layer to be pulled and easily form micro cracks. Therefore, it is necessary to control the cooling rate, the temperature should not exceed 10 ° C every 30 minutes; the temperature difference in the maintenance room table is not more than 30 ° C, the product stretch film can be out of the room.

The temperature requirements of stretched film are very strict, and each time is not neglected. Different temperature environments will affect its quality and the role of its application. Therefore, in order to ensure the later use, the control of the environment We need to control it.

Warming phase

Under the premise of ensuring that the stretched film blank is not affected by the vapor, the temperature rise time should be as short as possible, and it is only necessary to continuously and uniformly deliver steam to the maintenance room for 1.0 to 1.5 hours.

Constant temperature stage

The constant temperature phase is an important stage in which the body is hydrated and hydrothermally composed to increase the strength. As the constant temperature time extends, the more the hydrates accumulate, the faster the strength increases. However, after the constant temperature reaches a certain time, the strength increases and the start becomes slower. Different material ratios, different production processes, and the output of the aerated block blanks have a corresponding constant temperature moment. For example, under the hot and humid conditions of 96 to 100 ° C, the constant temperature is 8 hours in spring and autumn, 7 hours in summer and 10 hours in winter. In the cooling stage, when the output is large and the maintenance room is not enough space, the maintenance room door should be opened and the rapid cooling will be adopted, which will cause the temperature difference stress between the surface of the stretched film body to cause the surface layer to be pulled and easily form micro cracks. Therefore, it is necessary to control the cooling rate, the temperature should not exceed 10 ° C every 30 minutes; the temperature difference in the maintenance room table is not more than 30 ° C, the product stretch film can be out of the room.

The temperature requirements of stretched film are very strict, and each time is not neglected. Different temperature environments will affect its quality and the role of its application. Therefore, in order to ensure the later use, the control of the environment We need to control it.

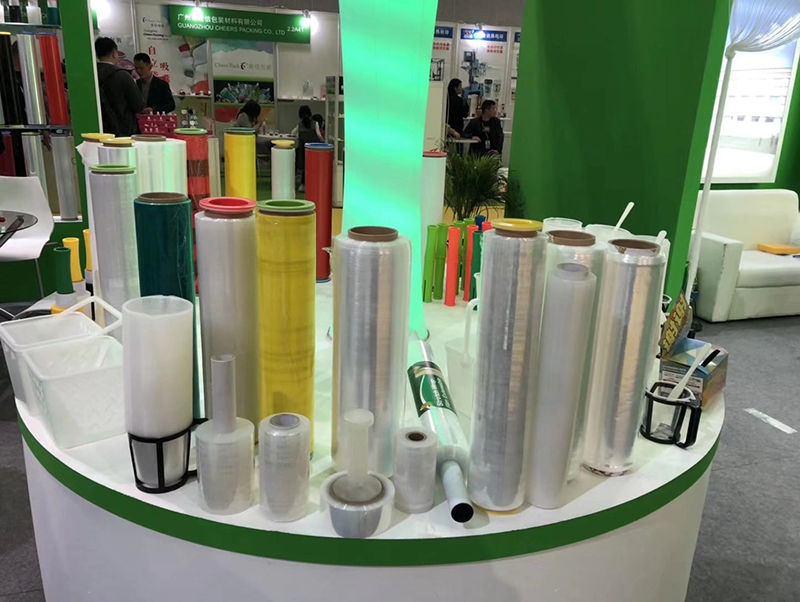

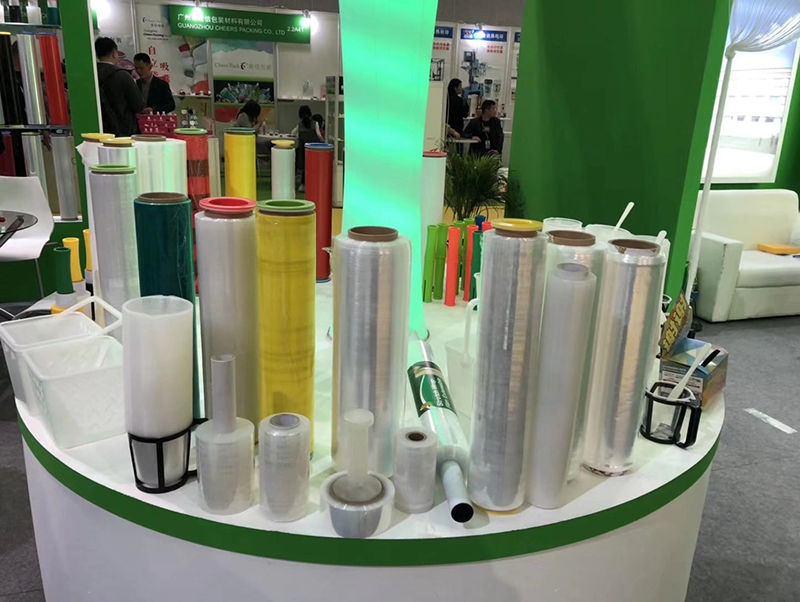

Recommended Products

Ranked in the same article

- how to use the stretch film technology to r

- Plastic film degradation

- How to guarantee punctual shipment for our

- Five common quality problems of PE protecti

- Why insufficient transparency of stretch w

- Standard for use of stretch films

- The use form of stretch film

- What is the difference between stretch film

- The elastic characteristics of plastic film

- Electrical wire film VS electrostatic film

- Uses of Stretch Wrap Film

Latest news articles

- How to save stretch film

- The feature of Stretch film and application

- The product has many more uses in pallet un

- How can we get detailed price list?

- Application field of stretch wrapping film

- How to guarantee punctual shipment for our

- Classification of stretched film

- Four characteristics of the wrapping film

- Calculation of the quality of stretched fil

- Classification and advantages of stretch fi

- The elastic characteristics of plastic film